AIoT Healthy Diagnostic Function for Solar Plant

Combining advanced AI algorithms with existing power plant data to create an AIoT intelligent monitoring system, providing tailor-made professional models as well as uninterrupted and diverse monitoring.

Analytical Features

Field

- Presentation of efficiency indicators and trend analysis

- Power Generation Achievement Tracking

- Aging Analysis

- List of items to be improved

- Emergency level of the item needed to be improved

- Economic Loss Estimation

Inverter

- Presentation of efficiency indicators and trend analysis

- Dust and dirt warning

- Improper shade

- Abnormal MPPT

- Circuit tripping off

- Device down rate due to Overheating

- Poor insulation

String

- Module defect

Pixel View Function

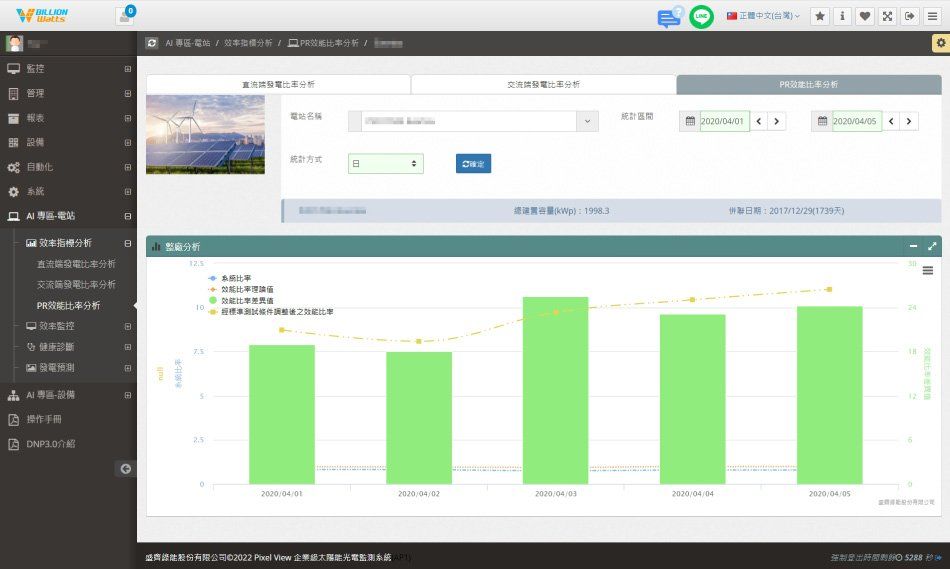

Overall Efficiency Index Analysis

The entire PR value, theoretical PR value and system loss are established through the 3-month historical data source. When an abnormality occurs, the machine is continuously monitored. The abnormality is reflected in the index value, and the early diagnosis is made to maintain stable power generation efficiency.

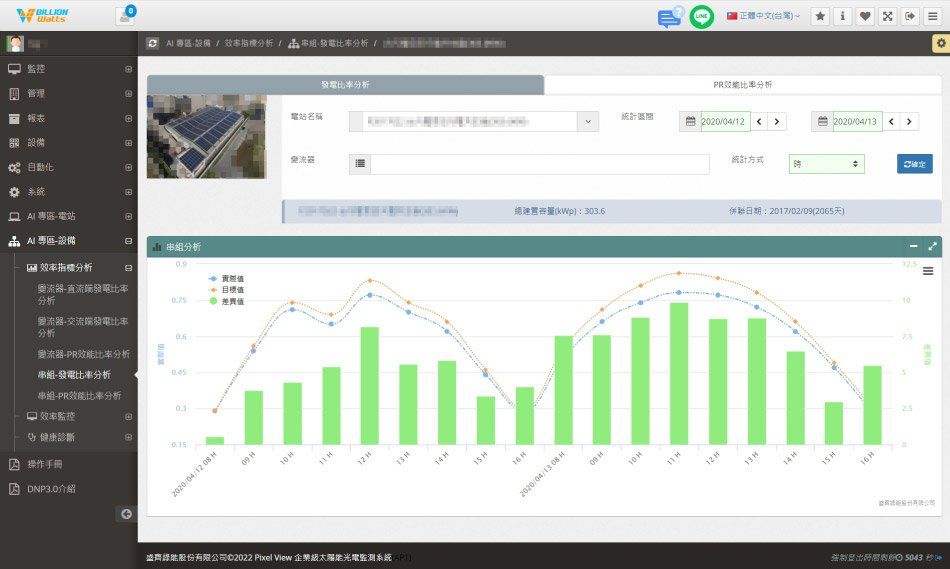

Equipment Efficiency Index Analysis

Establish comprehensive efficiency indicators of converters and strings. Through uninterrupted monitoring, the system will give an the alert notification when the equipment operates abnormally. The power station manager can arrange manpower according to the severity of the abnormality and focus the limited maintenance and operation resources on repairing the abnormality with the greatest benefit.

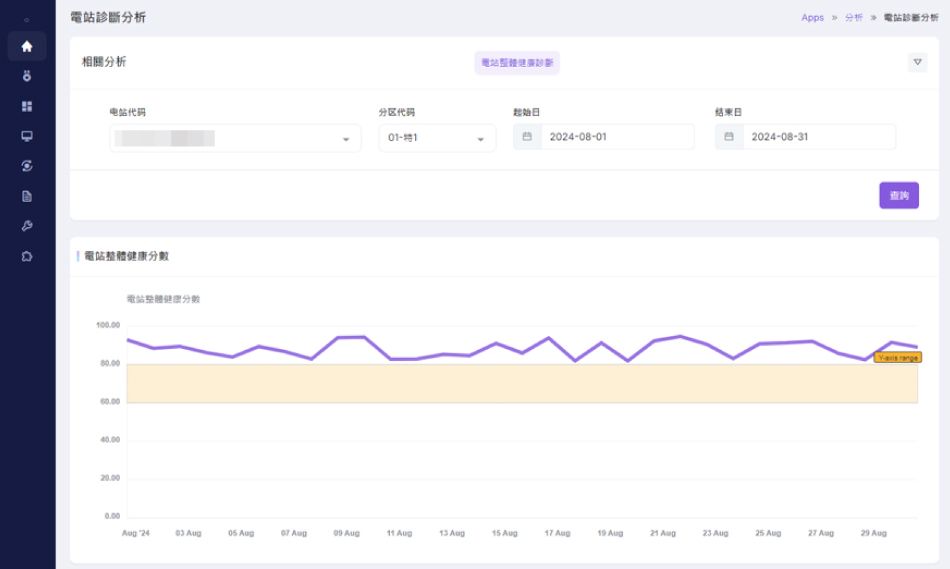

Precise Health Diagnosis

Create tailor-made monitoring indicators. When the potential abnormal status of equipment is complex, based on the physical rules and AIoT comprehensive judgment and analysis, the system can analyze and diagnose the cause of each abnormal fault in the power plant in detail, which can accurately provide fault attribution.

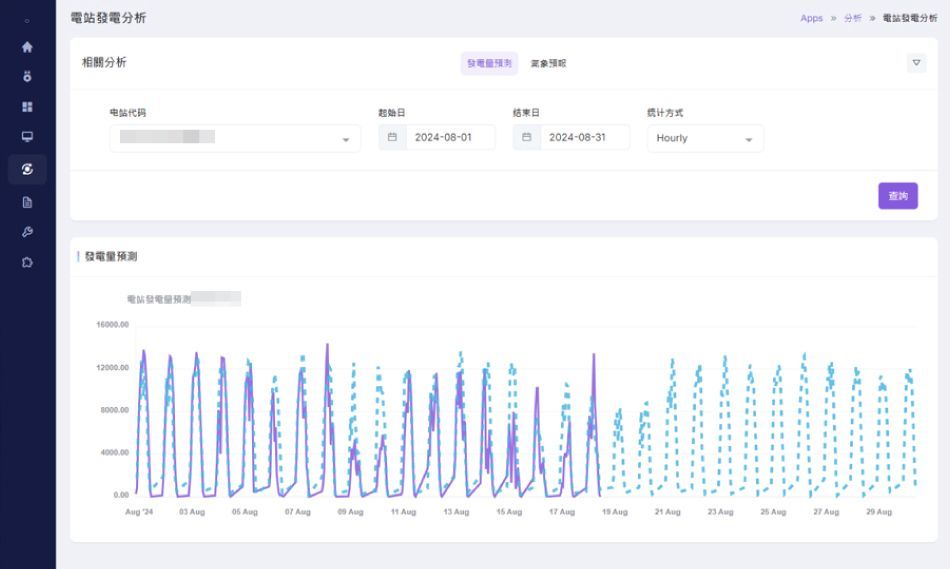

Power Generation Forecast Calculation

The pre-calculation of power generation at the "future" time can output renewable energy to energy storage equipment for the purpose of shaving load peaks and filling valleys, planning power distribution plans, and obtaining maximum economic benefits in the power market.

AIoT automatically diagnoses faults

- The "health condition" of each monitored component is automatically evaluated on a daily basis.

- Tailor-made monitoring indicators, through machine learning, can automatically adjust the calibration accuracy according to environmental changes.

Artificial Intelligence can do more with less effort

- Improve the efficiency of human resources – AIoT can replace or assist part of human work and help increase efficiency.

- Improve equipment efficiency – AIoT is like a device administrator who does not rest, automatically diagnosing the cause of failure, shortening the troubleshooting time, and increasing the efficiency of equipment use.

- Improve economic efficiency – The results of AIoT analysis provide managers with an accurate understanding of the current state of equipment operation, and can make optimal arrangements for related maintenance plans to improve investment efficiency.

Can I still use AIoT diagnosis instead of Billion Watts' Pixel View?

Billion Watts Pixel View advanced grid-level solar monitoring system is the basis for AIoT data collection. As long as more than 3 months of historical data are established in the Billion Watts Pixel View monitoring system, you can use this data to establish AI efficiency indicators for your power station and perform AIoT fault diagnosis. For customers willing to move to PixelView, we would like to offer a special favor for first-time users: your original existing environmental sensors (pyranometer, template thermometer, atmospheric thermometer, anemometer) and network sources (SIM card, WiFi, ADSL) can be integrated into PixelView for continuous use. Our data collector (SG6300NZL R2) can be integrated with any 3rd party weather station and converter as well as transmit all data to the cloud platform, providing better service quality and a wide range of additional features in the future.

Additional Features

AI Deep Learning

Diagnostics and Analysis Features

Uninterrupted AI

Automatically Scheduling Maintenance Checkpoints

Tailor-Made Whole Plant

Equipment Health Diagnosis

Calculate the Dust Accumulation Index Based on the Measurement Data for Remote Monitoring

Why is AI so important to solar power plants?

Today, we can use AI to check daily whether the millions of data of the power plant are abnormal or not. AIoT will use physical logic, machine learning, to establish indicators to find out the cause of the failure and predict the health of the solar power plant through automatic scheduling to prevent malfunction of power equipment. Maintenance engineers can troubleshoot based on the professional advice provided by powerful calculations to ensure that no human error or negligence occurs in the decision-making process, and at the same time, improve the correctness of the maintenance as well as improve the power generation efficiency, allowing investors to shorten the investment payback period and achieve higher revenue.